All Products

Portable Abrasive Blaster P-7 Sand Blasting Machine

The portable abrasive blaster/ sandblasting machine is a secure and efficient system designed to handle a variety of abrasive materials while achieving high productivity. It is suitable for working on metals, glass, stones, and ceramics. Operating on the principle of pressure blasting, the machine comprises a blast generator. Abrasives are loaded into the machine when it is not in operation and the blast generator is depressurised. A vibrating sieve at the top of the machine sifts the loaded abrasives, ensuring that any oversized abrasives and debris are captured on the screen to prevent blockages in the blast line. When the mushroom valve is opened, the abrasives are transferred to the blast generator for blasting. The mushroom valve closes when compressed air is activated and the abrasive storage tank is pressurised, allowing the abrasives to freely fall into the mixing tube. Compressed air then carries the abrasive from the mixing tube to the nozzle for blasting. The blast generator is fabricated from 6 mm thick steel plate as per IS-2825 standard and hydraulically tested at 250 psi.

Portable Abrasive Blaster P-7 Sand Blasting Machine

The portable abrasive blaster/ sandblasting machine is a secure and efficient system designed to handle a variety of abrasive materials while achieving high productivity. It is suitable for working on metals, glass, stones, and ceramics. Operating on the principle of pressure blasting, the machine comprises a blast generator. Abrasives are loaded into the machine when it is not in operation and the blast generator is depressurised. A vibrating sieve at the top of the machine sifts the loaded abrasives, ensuring that any oversized abrasives and debris are captured on the screen to prevent blockages in the blast line. When the mushroom valve is opened, the abrasives are transferred to the blast generator for blasting. The mushroom valve closes when compressed air is activated and the abrasive storage tank is pressurised, allowing the abrasives to freely fall into the mixing tube. Compressed air then carries the abrasive from the mixing tube to the nozzle for blasting. The blast generator is fabricated from 6 mm thick steel plate as per IS-2825 standard and hydraulically tested at 250 psi.

| Model | P7-150 | P7-301R | P7-501R | P7-1001R |

|---|---|---|---|---|

| Abrasive Capacity Metallic (Kg.) Sand (Kg.) Volume (Liters) | _ 15065 42 | _ 300130 85 | _ 500230 142 | _ 1000460 284 |

| Overall dimensions approx Height mm Diameter mm Weight Kg. | _ 1110360 95 | _ 1290460 140 | _ 1370615 180 | _ 1610760 245 |

| Blast Nozzle Tungsten Carbide lined Orifice mm [*Standard size supplied ] | *5 6 | *6 5 | *8 6,10 | *10 8,12 |

| Blast Hose ID (mm) Blast Hose Length (meter) Recommended Air Hose ID (mm) | 19 5 19 | 19 5 19 | 25 7.5 25 | 32 10 32 |

| Approx Cleaning Rate (Sq. Mtr./Hour) For guidance only | 3 to 4 | 5 to 9 | 11 to 15 | 15 to 19 |

| Compressed Air Requirement at 5.63 Kg./sq. Cm (80psi) Cubic meter/minute (CFM) | 1.27(45) | 2.41(85) | 3.85(135) | 7.08(250) |

| Recommended Abrasive size range BS Mesh | 30 to 80 | 25 to 80 | 16 to 80 | 12 to 80 |

Pressure Blaster(PB)/Pressure Blasting Cabinet Machine

Pressure Blasting Cabinet pressure blasting machine operates primarily on the direct pressure blasting principle. In these machines, the air line from the compressor is directly connected to the pressure pot. As compressed air moves through the system, it pressurise the pressure pot tank, causing the media to descend. When this media combines with a large volume of high-pressure air, it travels through the blast hose and exits from nozzle at a high pressure. This intense stream of abrasive material impacts the surface of the component. These machines typically feature a cabinet enclosure, ensuring that blasting operations are conducted within it to minimise worker exposure to airborne contaminants produced during the blasting process. a fabric bag-type dust collector is attached to the cabinet as a standard feature for high efficiency of dust collection. A manual shaker is also provided for bag shaking. Pressure blasting machine is recommended for fast cleaning and for removal of heavy rust and corrosion using coarse abrasive.

| Model | PB-9182 | PB-12090 | PB-150120 |

|---|---|---|---|

| Working Chamber (mm) Height Width Depth | _ 775910 820 | _ 9001200 900 | _ 9001500 1200 |

| Door Opening (mm) Width Height | _ 730675 | _ 800800 | _ 1100800 |

| Overall Dimension (mm) Height Width Depth | _ 21301100 2500 | _ 20301365 2430 | _ 28801665 2730 |

| Dust or Mist Collector or

Reclaimer Fan Motor HP Fan Capacity (M³/min) Fan Capacity (CFM) Filter Cloth Area (M²) Slurry Pump Motor (HP) Airjet Orifice mm Blast Nozzle mm[*Standard size supplied ] | 1.0 14.16 500 7.5 --- --- *5,6 | 1.0 14.16 500 7.5 --- --- *5,6 | 1.5 22.66 800 10.0 --- --- *5,6 |

| Abrasive Storage Capacity Litres (CFT) | 28(1.0) | 42(1.5) | 42(1.5) |

| Pit Size (mm) Width Length Depth | _ --- | 600 2180 510 | 900 2530 600 |

| Weight in Kg (appro.) | 580 | 650 | 760 |

| Abrasive Feed | Direct Pressure | ||

Suction Blaster(SB)/Suction Blasting Cabinet Machine

The Suction Blasting machine/ super blaster operates on the principle of induction-suction for delivering abrasive materials. In this system, air flows through the gun, creating a suction effect that draws up abrasive particles and delivers them to the nozzle, where they are propelled toward the target surface. Typically, lightweight media is used in suction blasters. The abrasive is continuously distributed from the storage tank to the blast gun without interrupting the blasting process. These machines are equipped with a cabinet-type enclosure, ensuring that blasting operations are contained within the enclosure to minimise worker exposure to airborne contaminants generated during the process

| Model | SB-6060 | SB-9182 | SB-12090 |

|---|---|---|---|

| Working Chamber (mm) Height Width Depth | _ 600600 600 | _ 775910 820 | _ 9001200 900 |

| Door Opening (mm) Width Height | _ 500500 | _ 730675 | _ 800800 |

| Overall Dimension (mm) Height Width Depth | _ 1660800 1500 | _ 21201070 1400 | _ 25701365 1700 |

| Dust or Mist Collector or

Reclaimer Fan Motor HP Fan Capacity (M³/min) Fan Capacity (CFM) Filter Cloth Area (M²) Slurry Pump Motor (HP) Airjet Orifice mm Blast Nozzle mm | 0.5 5.66 200 1.0 --- *2,3 *6,8 | 1.0 11.32 400 2.0 --- *3,4,5.5 *8,10,12 | 1.5 16.98 600 4.0 --- 3,*4,5.5 8,*10,12 |

| Abrasive Storage Capacity Litres (CFT) | 28(1.0) | 28(1.0) | 42(1.5) |

| Pit Size (mm) Width Length Depth | _ --- | _ --- | _ --- |

| Weight in Kg (appro.) | 250 | 380 | 490 |

| Abrasive Feed | Induction Suction | ||

Tumblast Shot Blasting Machine

The Tumblast type shot blasting machines are renowned for their robustness, durability, and reliability across diverse working environments. Engineered to efficiently handle a range of tasks including cleaning and peening, they excel in delivering superior results in less time compared to other machine models. Tumblast type machines are basically designed for batch type operation.Components to be blasted are loaded on to the endless rubber conveyor of the machine from this door. One No. of Blast wheel unit, is strategically placed at the top of the Blast cabinet will fire abrasive at high velocity on the tumbling components and blast cleans them thoroughly. Tumbling action of the rubber belt conveyor ensures that each and every portion of the component will get exposed to the blast stream for through cleaning. Incorporating the latest blast wheel design, these machines are optimized to minimize maintenance costs while ensuring consistent performance.

| Particulars | TUMBLAST 20" x 27" | TUMBLAST 27" x 36" | TUMBLAST 36" x 42" |

|---|---|---|---|

| Tumbler (Basket) Size (mm) Drum Dia Drum Length | _ 500675 | _ 675900 | _ 9001050 |

| Size of Wheel (dia x width) | 12.5" x 2.5" | 15.5" x 2.5" | 19.5" x 2.5" |

| No. of Blast Wheel | 1 | 1 | 1 |

| Work Load Capacity Max. Weight of Each Piece (Kgs.) Max. Weight (Kgs.) Max. Weight of Each Piece (Kgs.) | - 280 8 | - 5200 15 | - 10500 50 |

| Power of Blast Wheel | 7.5 HP | 15 HP | 20 HP |

| Type of Dust Collector (As per demand) | Plain Fabric Bag / Pleated Bag | Plain Fabric Bag / Pleated Bag | Plain Fabric Bag / Pleated Bag |

| Total Power Consumption | 12.5 HP | 24 HP | 31.5 HP |

| Height of the Machine | 4000mm | 5200mm | 6000mm |

| Requirement of Pit | No | No | No |

| Note: Above specifications are approximate and are subject to change without notice. | |||

Swing Table Shot Blasting Machine

Surface has a range of Airless swing table type shot blasting machine.Table type shot blast machines are designed and built as fully integrated blast cleaning systems to handle larger or more fragile castings. Machine consists of Vertical door with a table type work/job handling system. This table is directly mounted on the door and it rotates on its own axis. Blast wheel unit is strategically placed at the top of the Blast cabinet will fire abrasive at high velocity on the components placed on the rotating work table and blast cleans them thoroughly. Rotational mechanism of table ensures that component will get exposed to the blast stream for through cleaning.The machine is designed for efficient removing after scales from components after heat treatment , forgings and cleaning of pro-plating and pre-anodized articles, alloy steel and Aluminium alloy castings/materials. These machines can be supplied in one / two doors with table. The operation of machine is simple and automatic.

| Particulars | SWING TABLE-750 | SWING TABLE-1200 | SWING TABLE-1800 |

|---|---|---|---|

| Size of Wheel (dia x width) | 12.5" x 2.5" | 19.5" x 2.5" | 19.5" x 2.5" |

| No. of Blast Wheel | 1 | 1 | 1 |

| Power of Blast Wheel | 7.5 HP | 15 HP | 25 HP |

| No. of Swing Table (as per demand) | One / Two | One / Two | One / Two |

| Diameter of Swing Table | 750mm (30") | 1200mm (48") | 1800mm (72") |

| Maximum Load on Table | 350 Kg. | 750 Kg. | 2500 Kg. |

| Loading Height (mm) | 1125 | 950 | 950 |

| Maximum Job Height (mm) | 300 | 600 | 1000 |

| Type of Dust Collector (as per demand) | Plain Fabric Bag / Pleated Bag | Plain Fabric Bag / Pleated Bag | Plain Fabric Bag / Pleated Bag |

| Total Required Power (H.P.) | 12 | 23 | 36 |

| Height of the Machine | 4100mm | 4300mm | 5500mm |

| Requirement of the Pit | No | No | No |

| Note: Above specifications are approximate and are subject to change without notice. | |||

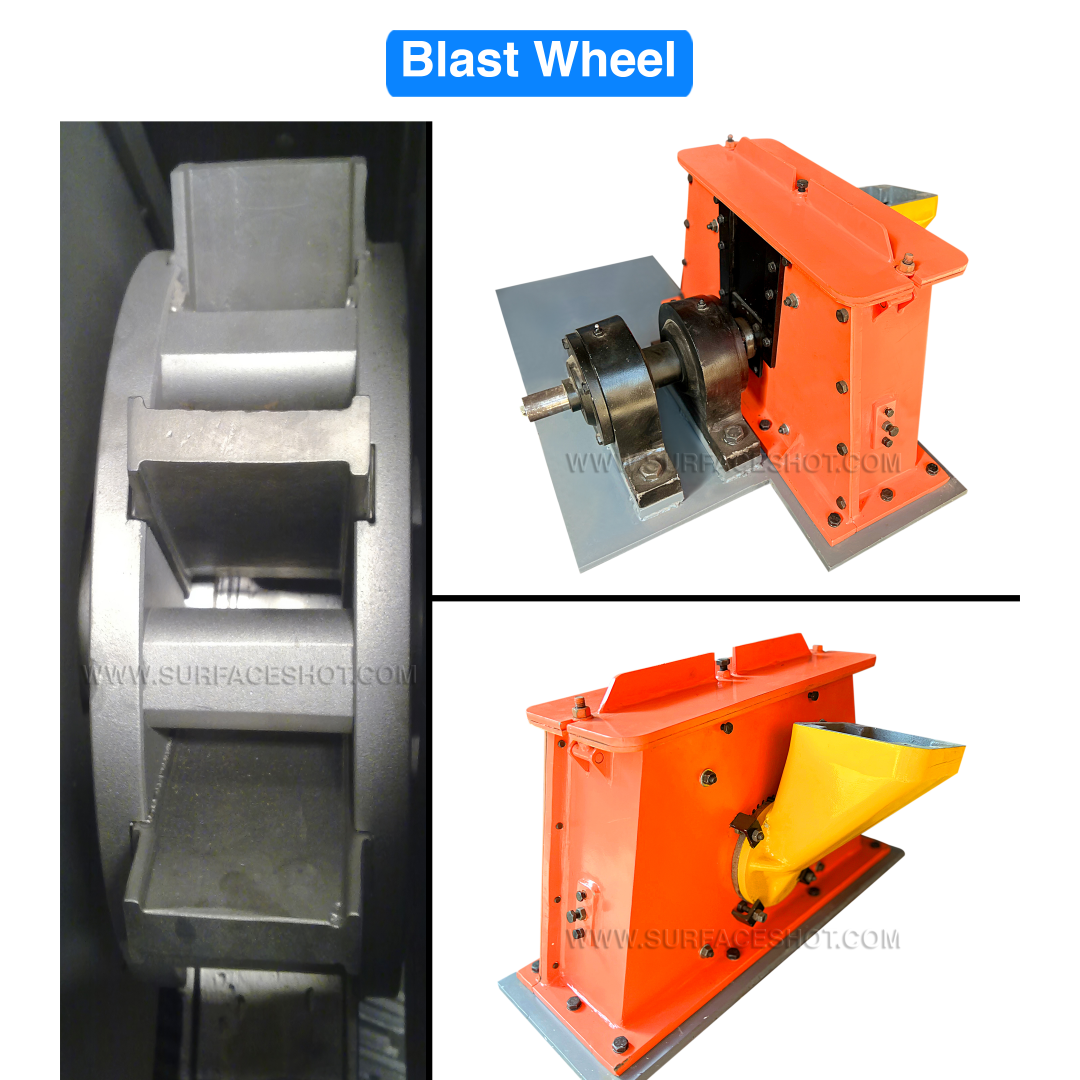

Blast Wheel

The blast wheel assembly is a critical component of the shot blasting machine, directly influencing the effectiveness of the blasting process. At surface, we prioritise quality and performance in our blast wheel designs, aimed at enhancing efficiency and durability across diverse applications.we manufacture both type of Blast wheels-

Direct-Drive Type Blast Wheel

Our direct-drive type blast wheels feature a compact structure where the motor is directly connected to the blast wheel via a shaft. This design not only improves efficiency but also reduces noise levels, ensuring easier maintenance. Typically, these units accommodate motors up to 15 hp, with a maximum blasting abrasive flow capacity of up to 180 kg/min.

Belt-Drive Type Blast Wheel

For applications requiring higher power and abrasive flow rates, we offer belt-drive type blast wheels. These units leverage a belt connection between the motor and blast wheel, allowing for increased power capabilities. With motor options extending up to 25 hp, they can achieve blasting abrasive flow capacities of up to 250 kg/min, making them suitable for demanding operations.

| Particulars | BW12.5 new | BW1215 | BW1519 |

|---|---|---|---|

| Motor Power Options (HP) | 5/7.5 | 10/15 | 15/20/25 |

Abrasive Media

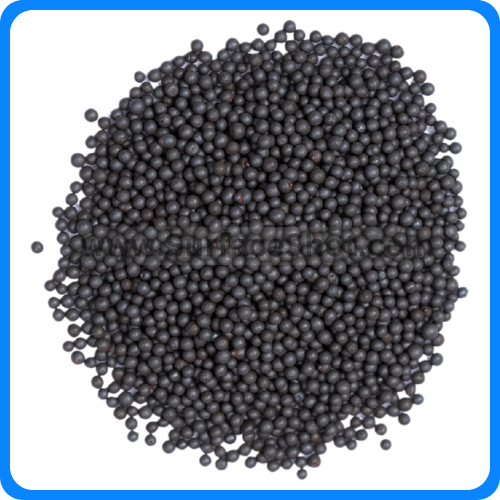

Steel Shot

Mesh Size: 8 - 52

Size mm : 2.00 - 0.30

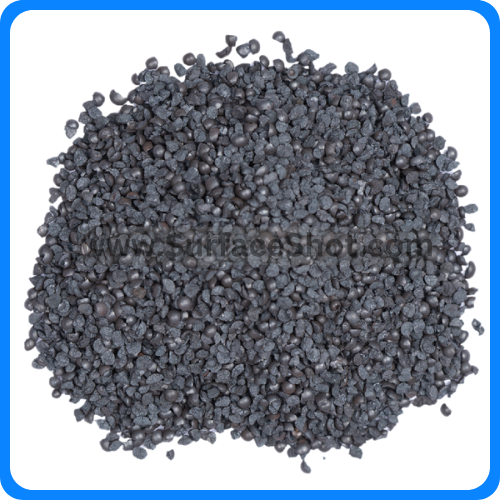

Steel Grit

Mesh Size: 12 - 52

Size mm : 1.40 - 0.30

Glass Beads

Mesh Size: 18 - 350

Size mm : 0.85 - 0.04

Aluminum Oxide

Mesh Size: 12 - 240

Size mm : 1.40 - 0.06

Garnet Sand

Mesh size:

12/24, 20/40, 30/60, 80/120

Size mm:

1.68-0.71, 0.84-0.42, 0.595 - 0.25, 0.177 - 0.125

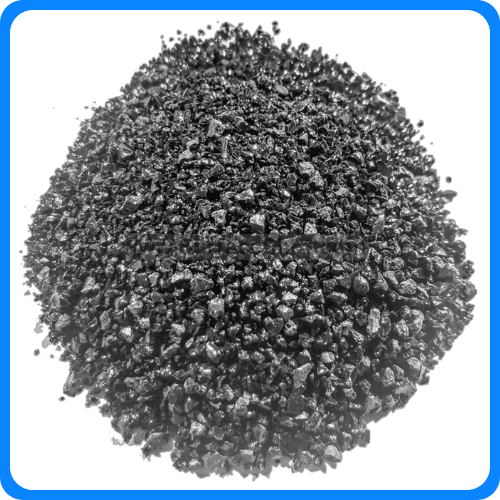

Copper Slag

Mesh size:

12/24, 20/40, 30/60, 80/120

Size mm:

1.68-0.71, 0.84-0.42, 0.595 - 0.25, 0.177 - 0.125

Pentoclean Acralic Grit

Mesh Size: 8 - 120

Size mm : 2.00 - 0.09

Steel Cut Wire

Mesh Size: 51 - 12

Size mm : 1.40 - 0.30

Operator Safety Wears

Airfed Blaster Helmet

Rubberised FRP helmet

Extra large window for clear view

Operator Suit

provides protection to the operators

Saves from impact of abrasives

Air Conditioner

Air conditioner make air cool to ensure comfortable environment for operator

Air Breather

Air breather consists of filter to purify incoming air supply

Hand Glove

Thick rubber hand gloves for protection

Gum Boot

Strong and durable sole gum boot

Spare Parts

Sandblasting Nozzles

Tungsten carbide and boron carbide nozzles

Size in 5,6,7,8,and 10 mm

Y-Gun

Aluminum / Steel body

Light weight

Remote

Remote ON/OFF of Machine

Provide added safety to operator

Exhaust Valve With Silencer

For the controlled release of air pressure from the blasting vessel with lower noice.

Nozzel Holder

Aluminum / Steel / Plastic Body

Quick assembling

DeadMan Handle

Remote ON/OFF of Machine

Provide added safety to operator

Mixing Tube

Cast Iron Casted Body

A air abrasive mixing chamber

Pinch Valve

For arduous service suitable for all abrasive media

Dump Valve

To preventing clogs, and easily refilled with fresh abrasive.

Grit Valve

For Proper regulation of grit flow

Mushroom Valve

The Mushroom Valve, normally closed self sealing, metering valve that can start and stop aggressive media

Sand valve

Precise abrasive flow can be easily controlled by two stainless steel discs, one stationary

Rubber 'o' rings and Diaphragm

All sizes available and high quality rubber

Vibrator

Aluminum Casted Body

Efficient vibration for abrasive sieving

Pinch valve sleeve

High quality rubber sleeve to regulate abrasive

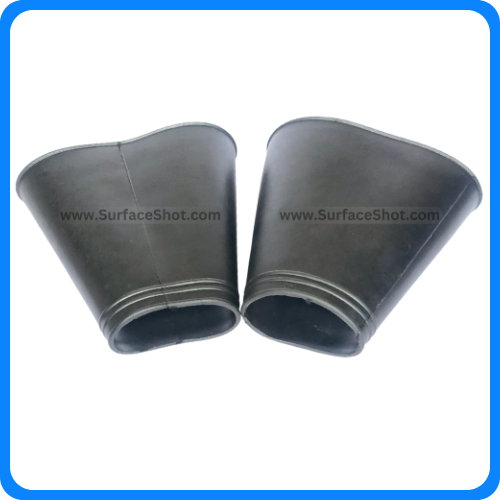

Rubber Gauntlet

Protect forehand in blast cabinet

Blasting hose

Highly abrasion resistance

Flexibility with lower bend radius

Helmet hose

Air conditioner cools air to helmet

comfortable environment

Filter bags

Cotton Filter Bags (Low Cost)

Polyester Filter Bags (long durability)

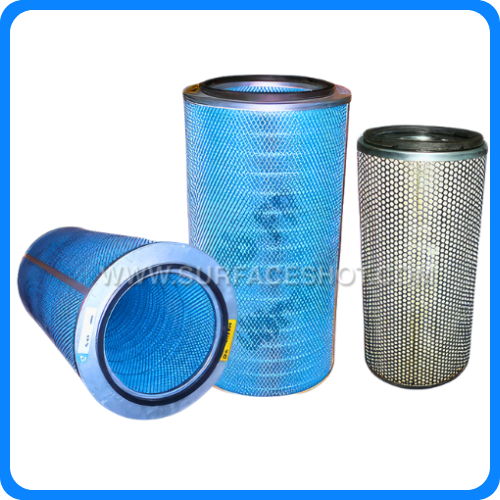

Cartridge Filte

Imported Quality HT - 405

Imported Quality HT - 660

PB mixing tube

Cast Iron Casted Body

A air abrasive mixing chamber

Pb pressure plate

For PB cabinet pressure vessel

Rotoblast

To clean internal surface of pipe, provided with 2 nozzles

Ball valve

S.S. Ball valve in 19mm, 25mm, 32mm, and 38mm

Air filter

Filter the air coming from compressor. available in 1/2 inch and 1 inch and 1 1/4 inch size

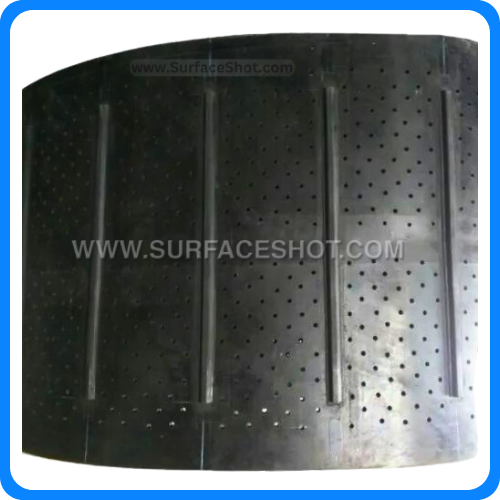

Rubber sheet

Natural Rubber wear resistance

40 to 45 Shore Hardness

Soundabrator

For noise and abrasive control

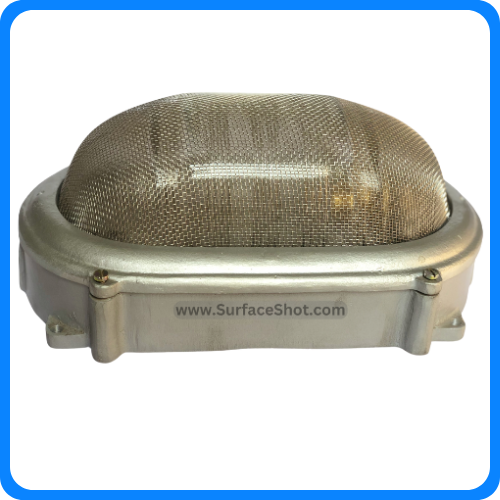

Light

Special light with net cover on glass for blast cabinet

Bucket elevator

Elevator pulley

Bearing assembly